Research

home

Fundamental Research for Producing High-Purity & High-Cleanliness Stainless Steels

Refining of High-Mn Steels for Generation Applications

Applications of Computational Thermodynamics for Producing High-Clean Steels ; Focusing on Smart Manufacturing

Novel Manufacturing Processes for Advanced High-Entropy Alloys

Grain Refinement of Macro-& Microstructure of Steels using Non-Metallic Inclusion

Zn-AI-Fe Dross Formation Mechanism in Hot Dip Galvanizing Bath for Producing Advanced Automotive Sreels

Physical Chemistry of MnO-base Slags for Producing High-Functional Manganese Ferroalloys

Viscosity-Structure Relationship of Molten Slags and Glasses

High Temperature Physical Chemistry of Metals and Slags

Characterization of Chemical Reactions at Slag-Refractory Interface in High Temperature Reactors

Extraction and Purification of Titanium and Its Alloys

Physical Chemistry of Molten Salts for Producing Magnesium and Zirconium

Recovery of Precious- & Rare Metals from Electric Wastes and Industrial By-products ;Foucusing on Circular Economy

Refining of High-Mn Steels for Next Generation Applications

(차세대 자동차용 High-Mn Steel의 제강 및 정련특성 규명)

Interfacial reaction between CaO-SiO2-Al2O3-MgO flux and Fe-xMn-yAl (x=10, 20 mass pct, y=1, 3, 6 mass pct) steel melts at 1873 K

(Kim and Park; Metall. Mater. Trans. B, 2012, vol.43B, pp. 875-886)

Development of advanced automotive steels has motivated studies into fully austenitic high-Mn steels like TRIP and TWIP steels with valuable mechanical properties such as high strength and good ductility. Additionally, weight reduction has become an important issue in the steel and automotive industries, as has the problem of greenhouse gas emissions. These factors have stimulated the development of a new class of light-weight steels containing a significant amount of Al. The addition of Al into high-Mn steels not only reduces the specific weight, but it also increases the stacking fault energy, which strongly affects the deformation mechanisms. Furthermore, Al has been shown to effectively suppress delayed fractures in the press-formed parts of TWIP steel.

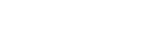

Changes in the composition of slags before and after the interfacial reaction at 1873 K

for (a) 1 mass pct Al-containing systems and (b) 3 to 6 mass pct Al-containing systems.

for (a) 1 mass pct Al-containing systems and (b) 3 to 6 mass pct Al-containing systems.

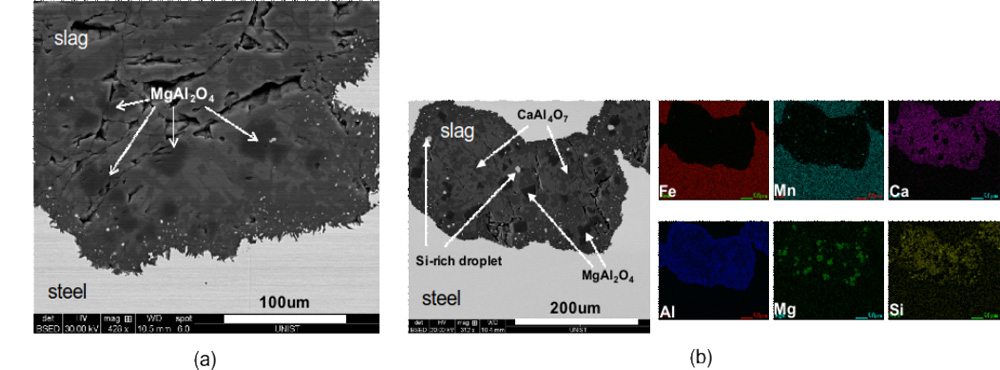

SEM-EDS and element mapping analysis for the slag/metal interface in the case of (a) Fe-10 pct Mn-3 pct Al and (b) Fe-20 pct Mn-3 pct Al systems.

Characterization of Non metallic Inclusions in High Manganese and Aluminum-Alloyed Austenitic Steels

(Park et al.; Metall. Mater. Trans. A, 2012, vol.43A, pp. 2316-2324)

Recent attention has been paid to the development of advanced automotive steels to fully austenitic high Mn steels showing very good mechanical properties such as high strength and good ductility, represented by TRIP and TWIP steels. In addition to the mechanical properties, weight reduction becomes an important issue in the steel and automotive industries in response to the very high cost of Mn alloys, as well as the problem of greenhouse gas emissions. This has stimulated the development of a new class of light-weight steels containing a significant amount of aluminum. Several Al-containing austenitic high Mn steels have been reported to exhibit good mechanical properties comparable to those of conventional TWIP steels. The addition of Al into high Mn steels not only reduces the specific weight, but also increases the stacking fault energy, which strongly affects the deformation mechanisms. The role of Al in TWIP steels has also received much attention because Al has been shown to effectively suppress delayed fracture in press-formed parts.

Even though much attention has been paid to the mechanical properties and fracture mechanisms of high Mn-Al alloyed steels, the influence of non metallic inclusions on the physicochemical properties of high Mn TRIP and/or TWIP steels has been noted very recently. Unfortunately, there has been very little systematic analysis or characterization of inclusions in high Mn and high Mn-Al alloyed steels. The effects of Al and Mn contents on the formations of oxide, nitride, and sulfide compounds in high Mn-Al alloyed steels are still unknown.

Therefore, in the present study, the effects of Al and Mn contents on the size, composition and three-dimensional morphologies of inclusions were investigated to enhance our understanding of the inclusion formation behavior in high Mn-Al alloyed steels.

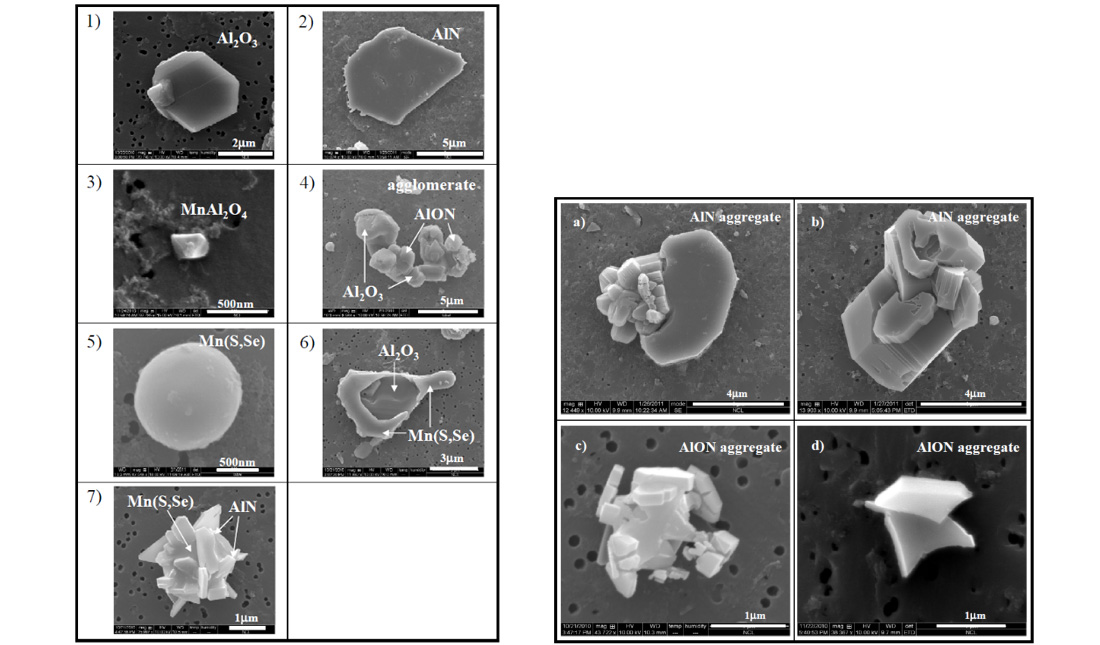

Morphologies of inclusions. Type 1) Al2O3; type 2) AlN or AlON; type 3) MnAl2O4 galaxite; type 4) Al2O3(-Al(O)N) agglomerate; type 5) Mn(S,Se); type 6) oxide core with Mn(S,Se) skin (wrap); and type 7) Mn(S,Se) core with Al2O3(-Al(O)N) aggregate (or bump).

Morphologies of AlN aggregates in (a,b) Fe-10Mn-3Al steels, and of AlON aggregates in (c) Fe-10Mn-6Al steel and (d) Fe-20Mn-6Al steel.

Solubility of Nitrogen in High Manganese Steel (HMnS) Melts: Interaction Parameter between Mn and N

(Shin, Lee, Min and Park; Metall. Mater. Trans. B, 2011, vol.42B, pp.1081-1085)

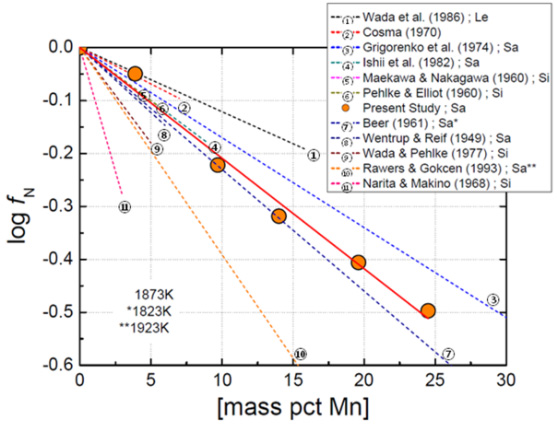

High manganese steels (HMnS; 10 to 25 mass pct Mn) are of interest due to their good mechanical properties such as superior strength and good ductility. The effects of nitrogen on the properties and microstructures of HMnS have been investigated by several authors. Recently, the nitride inclusions, e.g., AlN formed during steelmaking and continuous casting processes, was shown to affect not only the surface qualities but also the microstructures of steel products. Therefore, the N content in molten HMnS should be tightly controlled during manufacturing at high temperatures. However, reliable thermodynamic data for N solubility and the interaction parameter between Mn and N in HMnS melts are required in order to control the formation of AlN.

Even though many authors have measured the solubility of N in molten Fe-Mn alloy melts, there have been relatively large discrepancies in the interaction parameter between Mn and N for molten alloys, which ranges from about -0.04 to -0.01 at 1873 K and the temperature dependency of interaction parameter between Mn and N for high Mn content is largely lacking. This inconsistency in thermodynamic information results in uncertainty in estimating the formation behavior of nitride inclusions in HMnS.

Hence, we assessed the solubility of nitrogen under p(N2)=1atm using a N2 gas bubbling methodology from 1823 to 1923 K. We used our results to derive an expression for the interaction parameter between Mn and N as a function of temperature.

Comparison of present result to that of previous work (Sa: Sampling, Si: Sievert, Le: Levitation).