Research

home

Fundamental Research for Producing High-Purity & High-Cleanliness Stainless Steels

Refining of High-Mn Steels for Generation Applications

Applications of Computational Thermodynamics for Producing High-Clean Steels ; Focusing on Smart Manufacturing

Novel Manufacturing Processes for Advanced High-Entropy Alloys

Grain Refinement of Macro-& Microstructure of Steels using Non-Metallic Inclusion

Zn-AI-Fe Dross Formation Mechanism in Hot Dip Galvanizing Bath for Producing Advanced Automotive Sreels

Physical Chemistry of MnO-base Slags for Producing High-Functional Manganese Ferroalloys

Viscosity-Structure Relationship of Molten Slags and Glasses

High Temperature Physical Chemistry of Metals and Slags

Characterization of Chemical Reactions at Slag-Refractory Interface in High Temperature Reactors

Extraction and Purification of Titanium and Its Alloys

Physical Chemistry of Molten Salts for Producing Magnesium and Zirconium

Recovery of Precious- & Rare Metals from Electric Wastes and Industrial By-products ;Foucusing on Circular Economy

Grain Refinement of Macro- &

Microstructure of Steels using Non-Metallic Inclusions

(비금속 개재물을 이용한 철강재료의 조직 미세화 방안 연구)

Effect of nitrogen on grain growth and formability of Ti-stabilized ferritic stainless steel

(Lee, Kim and Park: Scientific Reports, 2019, vol.9, article #6369, pp.1-11)

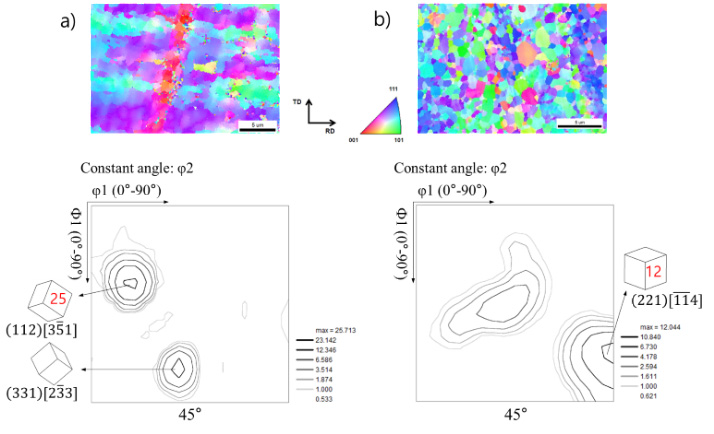

Ferritic stainless steels (FSSs) are widely used in automobile manufacturing and in various other fields because of their low thermal expansion and high resistance to corrosion. However, their limited formability due to ‘ridging’ defects must be resolved to expand their use. Ridging is typically observed on the surface of an FSS sheet after cold forming or deep drawing, degrading the surface quality of the sheet. Many researchers have observed that ridging arises from differences of plastic strain anisotropies between the matrix and colonies.

Even though there are many studies about refinement of the solidification structure in order to reduce ridging phenomenon, the effect of grain growth by pinning particles on the degree of ridging is not certain. Therefore, the aim of the present study is to evaluate the influence of the equiaxed grain formation in the cast samples and that of grain growth on the degree of ridging of final products, and to identify which is the more dominant factor affecting the ridging height. Hence, we analyzed the Zener pinning effect of TiN particles on grain boundaries and discussed its influence on grain growth during annealing at 1200oC.

EBSD inverse pole figure maps from ND plane and orientation distribution function (φ2 = 45°) of (a) 50 ppm N and (b) 140 ppm N containing sheets after cold rolling and annealing.

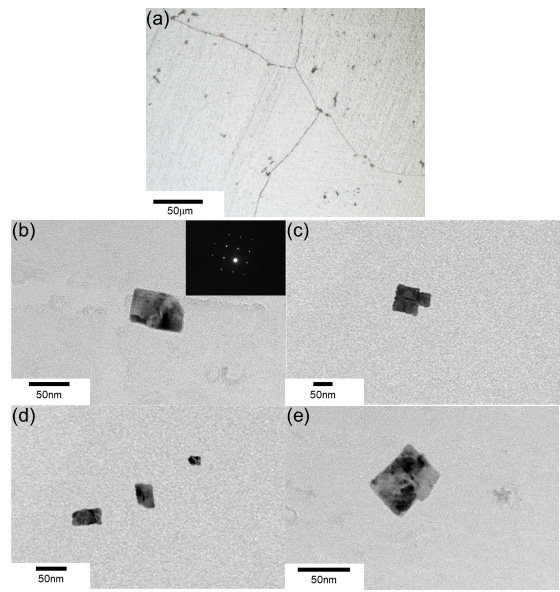

TiN particles after 10 min heat treatment. (a) TiN particles observed by optical microscopy; (b–e) TiN particles observed by TEM.

Synergistic effect of nitrogen and refractory material on TiN formation and equiaxed grain structure of ferritic stainless steel

(Lee and Park: Metall. Mater. Trans. B, 2018, vol.49B, pp.877-893)

Ferritic stainless steels (FSSs) are widely used in the automobile and manufacturing industries because of their low thermal expansion coefficient and high resistance to corrosion. However, limited formability due to the ‘ridging’ defect must be resolved to expand the use of FSS. Ridging is observed on the surface of a FSS sheet after cold forming or deep drawing which degrades the surface quality of the sheet. Several researchers observed that ridging occurs due to the difference of the plastic strain anisotropies between the colonies and matrix.

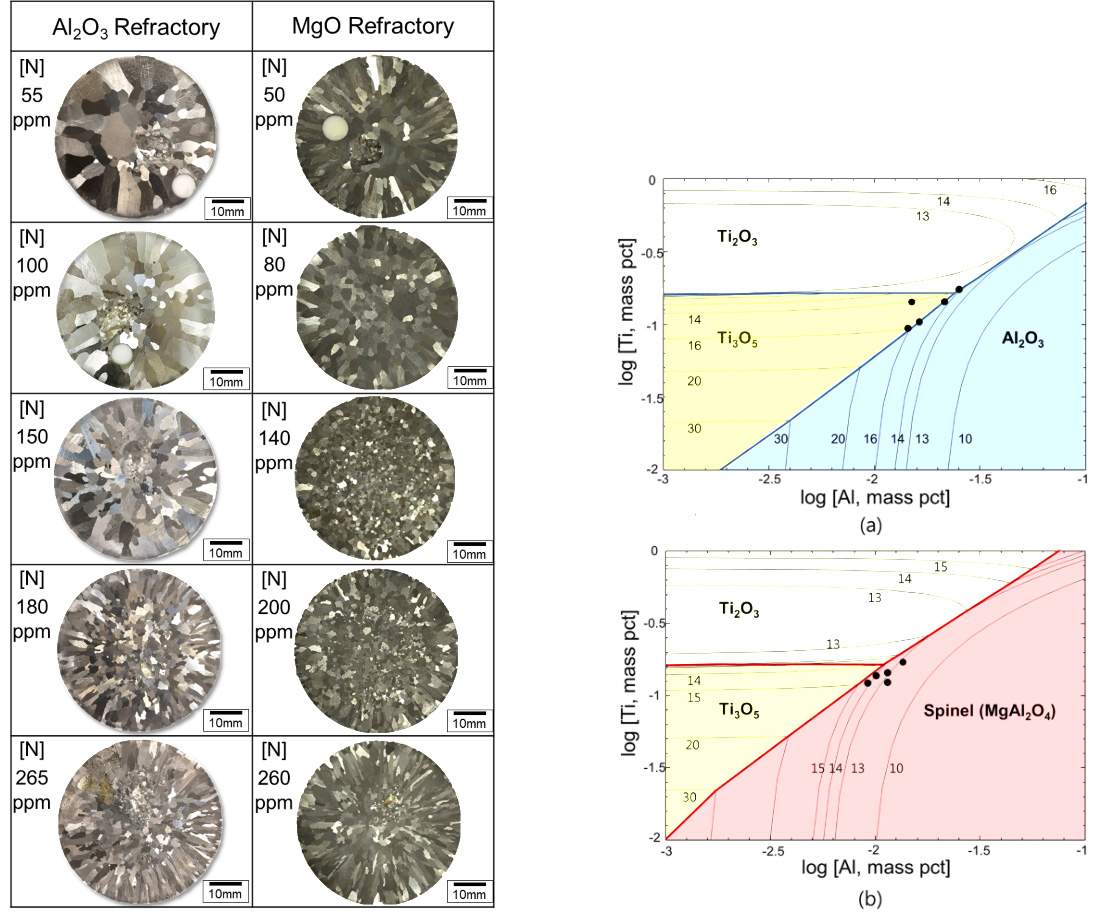

In the present study, we varied the nitrogen content, which is a key operating parameter in steel plants, to determine the effect of the nitrogen content on the formation of an equiaxed solidification structure by controlling the nucleation and growth process of TiN in Fe-16 mass pct Cr steel. Moreover, two different kinds of refractory materials widely used in the melt shop, alumina and magnesia, were employed to control the type of oxide inclusion (not by direct addition of deoxidizing elements such as Al, Mg, etc.). The characteristics of TiN and/or TiN-oxide hybrid inclusions such as the morphology, composition, number density, and size distributions were quantitatively analyzed in both molten steel and solidified samples. Finally, the nucleation and growth kinetics of TiN during the solidification of Ti-stabilized 16Cr FSS were predicted by considering the Ostwald ripening and diffusion-controlled growth model.

Solidification structures of sample cross sections.

The Ti-Al-Mg-O stability diagrams of oxides in the (a) Fe-16Cr-0.3Si-0.3Mn-0.004C and (b) Fe-16Cr-0.3Si-0.3Mn-0.004C-0.0001Mg melts at 1823 K calculated using the FactSageTM7.0 program.

Effect of Mg-Ti deoxidation on the formation behaviour of equiaxed crystals during rapid solidification of iron alloys

(Park et al.: Steel Res. Int., 2014, vol.85, pp.1303-1309)

Grain refinement is a way to improve the mechanical properties as well as to avoid segregation of elements during solidification of iron alloys. Therefore, some researchers investigated the heterogeneous nucleation of primary crystals on the surface of non-metallic inclusions, while the others have tried to apply the heterogeneous nucleation theory to practical operations such as welding and casting. The catalytic potential of various inclusions for the heterogeneous nucleation of primary delta ferrite during solidification of steel has been reported for several decades.

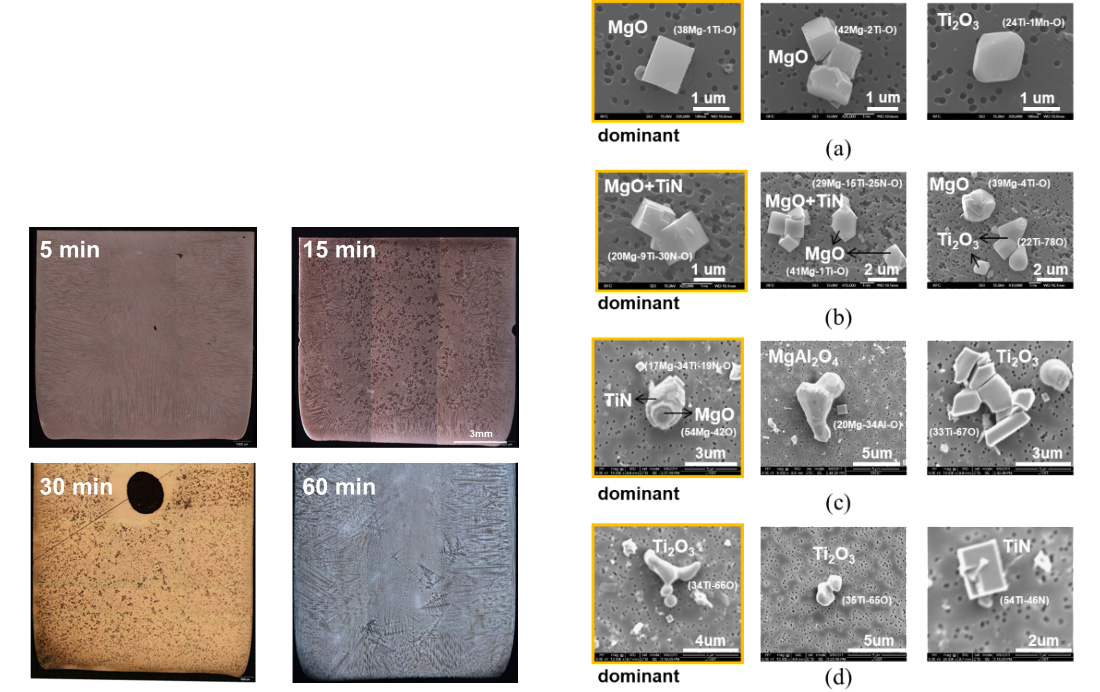

In the present study, the effect of complex inclusion on the solidification structure of iron alloy was investigated using direct melt sampling and quenching method. Moreover, the effect of complex oxides on the precipitation of TiN during rapid solidification of iron alloys was discussed.

Optical microscopy of solidified structures.

SEM image and EDS data (at%) including typical inclusion morphology in 5 min a), 15 min b), 30 min c), and 60 min d).

Effect of Complex Inclusion Particles on the Solidification Structure of Fe-Ni-Mn-Mo Alloy

(Park et al.: Metall. Mater. Trans. B, 2012, vol.43B, pp.1550-1564)

Grain refinement has been investigated as an approach to improve the mechanical properties of steel welds. Several research groups have attempted to refine the grain size of the heat affected zone (HAZ) by enhancing the nucleation of acicular ferrite on the surfaces of oxide and sulfide inclusions. Several experimental and model-based studies have been performed to understand the fundamental phenomena underlying the heterogeneous nucleation of delta ferrite in various kinds of substrate particles during solidification processes.

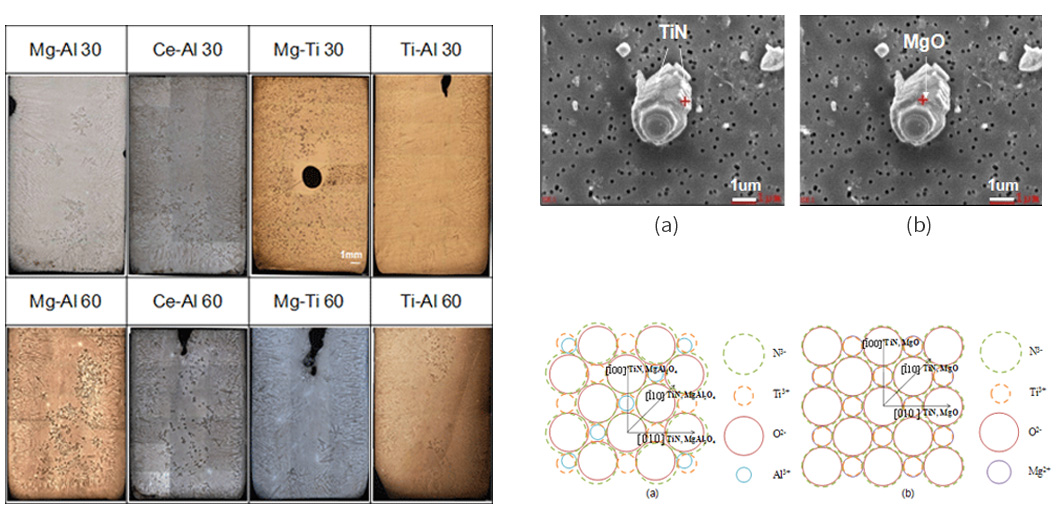

Recently, Park investigated the formation of TiN single particles as well as MgAl2O4–TiN complex particles in Ti-containing ferritic (11%Cr) stainless steel and found that inclusion of these particles resulted in a fine equiaxed structure due to low disregistry not only between TiN and delta ferrite, but also between TiN and MgAl2O4 spinel. A bimodal distribution of the above non-metallic compounds was critically important to refine the solidification structure.

In the present study, we therefore investigated the effects of combinations of several deoxidizers, i.e. Mg-Al, Mg-Ti, Al-Ti, and Ce-Al, on the solidification structure of Fe-Ni-Mn-Mo alloy melt using a melt sampling and quenching methodology. By employing this method, which we chose to simulate the very fast cooling conditions during welding, we were able to evaluate the catalytic potency of several complex inclusion particles by taking the inclusion evolution process into account.

Optical microscopy of solidified structures of deoxidized samples

SEM image including a complex inclusion in case of Mg-Ti added 30 minute sample.

The crystallographic relationship at the interface between the (100)TiN and the (100)MgAl2O4 (a), and between the (100)TiN and the (100)MgO (b).

Effect of inclusions on the solidification structures of ferritic stainless steel: Computational and experimental study of inclusion evolution

(Park; CALPHAD, 2011, vol.35, pp. 455-462)

erritic stainless steel (FSS) sheets develop an undesirable surface corrugation known as ridging when pulled or deeply drawn. The resulting FSS exhibits undulation, with peaks on one side of the sheet coinciding with valleys on the other side, without a change in the thickness. The ridges have a depth of 20-50 mm and the undesirable surface defect adds manufacturing costs through the need for polishing. Because the solidified structure is one of the most critical factors affecting the texture and thus the ridging phenomenon of FSS sheets, the columnar-to-equiaxed transition (CET) during the solidification process has been investigated in order to obtain an equiaxed grain structure of FSS. There have been several trials to apply the EMS technology, to control the superheating or undercooling, and to control the casting speed. However, these parameters are generally controlled within a very narrow operational window during the continuous casting process with regard to the stability and production rate of a daily operation.

Alternatively, the grain refinement of the solidification structure of steel welds has been investigated for mechanical properties, such as strength and toughness. There are several reports elucidating the effect of Ti on the refinement of the solidified grain of the weld pool of FSS. The addition of Ti resulted in the formation of Ti-rich oxide and nitride in the liquid phase. These particles could become heterogeneous nucleation sites of delta-ferrite during solidification.

Even though there was no objection to the role of TiN during crystallization of primary delta-ferrite, the effect of Al and its oxide on grain refinement has not been clarified. Therefore, in the present study, we investigated the effects of MgO-Al2O3 oxide and TiN inclusion particles, formed in-situ by addition of Al and Ti, in a steel melt on the formation of equiaxed grains during solidification of FSS. Further, the evolution and the phase equilibria of oxide and nitride inclusions have been predicted using a thermochemical computing program.

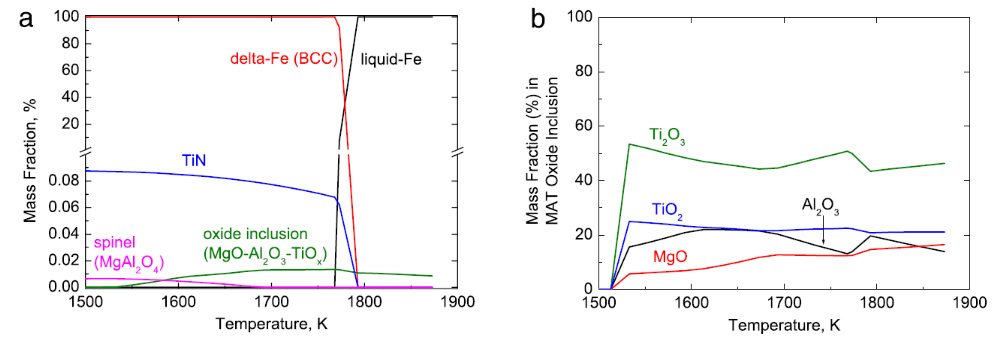

Mass fractions of metal, oxide and nitride phases with regard to temperature.

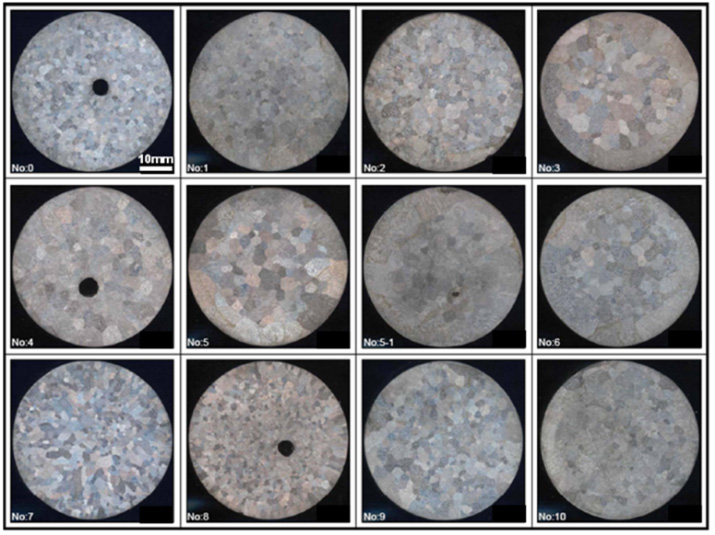

Solidified structures of ferritic stainless steel samples.

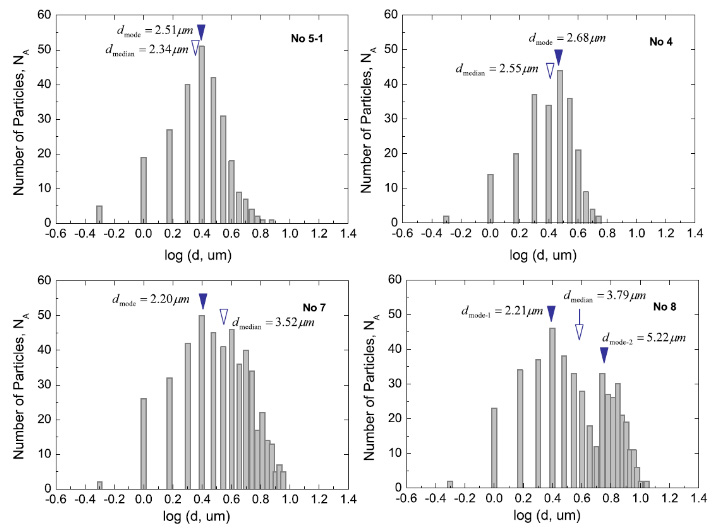

Particle size distribution of steel samples (dmode ; mode diameter, dmedian ; median diameter)