Research

home

Fundamental Research for Producing High-Purity & High-Cleanliness Stainless Steels

Refining of High-Mn Steels for Generation Applications

Applications of Computational Thermodynamics for Producing High-Clean Steels ; Focusing on Smart Manufacturing

Novel Manufacturing Processes for Advanced High-Entropy Alloys

Grain Refinement of Macro-& Microstructure of Steels using Non-Metallic Inclusion

Zn-AI-Fe Dross Formation Mechanism in Hot Dip Galvanizing Bath for Producing Advanced Automotive Sreels

Physical Chemistry of MnO-base Slags for Producing High-Functional Manganese Ferroalloys

Viscosity-Structure Relationship of Molten Slags and Glasses

High Temperature Physical Chemistry of Metals and Slags

Characterization of Chemical Reactions at Slag-Refractory Interface in High Temperature Reactors

Extraction and Purification of Titanium and Its Alloys

Physical Chemistry of Molten Salts for Producing Magnesium and Zirconium

Recovery of Precious- & Rare Metals from Electric Wastes and Industrial By-products ;Foucusing on Circular Economy

Novel Manufacturing Processes

for Advanced High-Entropy Alloys

(고엔트로피 합금의 성능 고도화를 위한 제조공정 최적화

collaboration with Dr. YS Na, KIMS, Prof. NK Park, Yeungnam University,

and Prof. JK Kim, Hanyang University)

Heterogeneous grain size and enhanced hardness by precipitation of the BCC particles in medium entropy Fe-Ni-Cr alloys

(Yang, Kang, Carsbring, Mu, Hedström, Kim, and Park; J. Alloys & Compd., 2023, vol. 931, article no. 167580)

The development of high-entropy alloys (HEAs) and medium-entropy alloys (MEAs), consisting of more than three principal elements, has greatly expanded the available composition space of next-generation metallic materials with outstanding mechanical properties. Early studies on HEAs and MEAs have mainly focused on alloys with a single face-centered cubic (FCC) structure because of their promising properties, such as excellent cryogenic properties, outstanding creep behavior, high resistance to shear localization, and strong resistance to hydrogen embrittlement. However, the relatively low strength of single-phase FCC materials has restricted their industrial applications. Thus, significant efforts have been devoted to improving the strength of HEAs and MEAs.

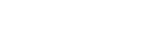

In the present work, we report the chemical-composition-dependent precipitation of Cr-rich BCC particles and their role in the hardening of Fe–Cr–Ni MEAs. Three MEAs with different chemical compositions: 33Fe–32Cr–35Ni (hereafter denoted as 33Fe), 40Fe–30Cr–30Ni (40Fe), and 45Fe–30Cr–25Ni (45Fe) (at%), were investigated. A detailed characterization of the microstructures after different annealing processes is presented, and the correlation between the microstructures and mechanical properties of the investigated alloys is discussed.

The equilibrium phase fraction as a function of temperature ranging from 300 to 1500°C for (a) 33Fe MEA, (b) 40Fe MEA, and (c) 45Fe MEA. (d) XRD patterns of materials annealed at 800°C for 100 h. (e) The dotted box region in (d) shows the minor peaks of the σ-phase in 45Fe alloy.

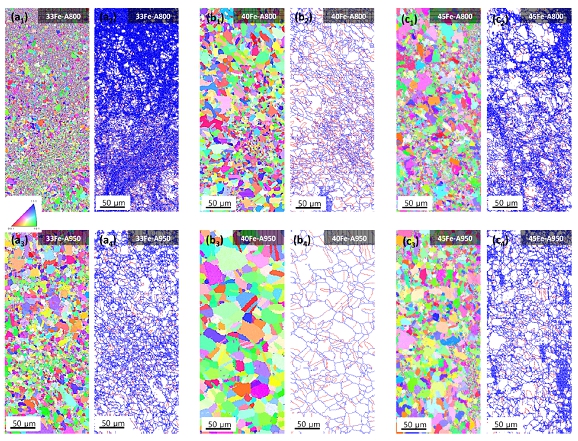

EBSD inverse pole figure maps and grain boundary maps for (a1)–(a2) 33Fe-A800, (a3)–(a4) 33Fe-A950, (b1)–(b2) 40Fe-A800, (b3)–(b4) 40Fe-A950, (c1)–(c2) 45Fe-A800, and (c3)–(c4) 45Fe-A950. In grain boundary maps, high-angle grain boundaries and Σ3 annealing twin boundaries are indicated by blue and red lines, respectively.

Role of recrystallization and second phases on mechanical properties of a (CoCrFeMnNi)95.2Al3.2Ti1.6 high entropy alloy

(Kang, NK Park, Kim and JH Park; Mater. Sci. Eng. A, 2021, vol.814, article number 141249)

High-entropy alloy (HEA) is a novel class of material consisting of several principal elements with equiatomic or near-equiatomic ratios. HEA often shows simple crystal structures such as FCC and BCC, which results in promising mechanical properties. The most extensively studied equiatomic CoCrFeMnNi HEA, referred to as the Cantor alloy, shows high FCC phase stability in a wide range of temperatures and promising mechanical properties with an excellent combination of strength, ductility, and toughness at both room temperature and cryogenic temperatures. However, yield strength (YS) of the alloy at room temperature is rather low, and the previous research focused on improving YS of the CoCrFeMnNi HEA by grain refinement and precipitation hardening by alloying additional elements.

The present work reports microstructures and mechanical properties of the homogenized and cold-rolled (CoCrFeMnNi)95.2Al3.2Ti1.6 (at.%) HEA annealed at various temperatures. The investigated material shows the formation of the σ and B2 second phase particles upon annealing. We discuss the relationship among microstructures, deformation mechanisms, and mechanical properties of the investigated material considering the effect of recrystallization, grain size, and second phases.

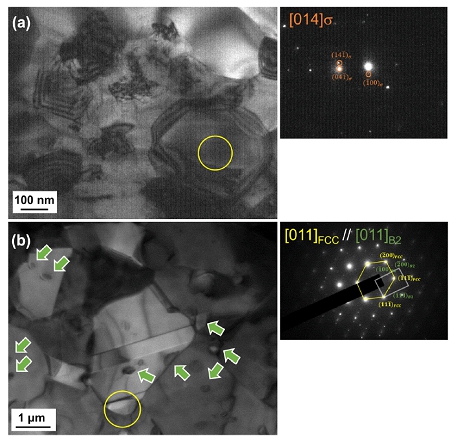

BF image and SADP of (a) HEA-700 and (b) HEA-900. The yellow circles indicate the regions where diffraction patterns were obtained, and the green arrows indicate B2 precipitates.

Investigation on the precipitate formation and behavior in nitrogen-containing equiatomic CoCrFeMnNi high-entropy alloy

(Jodi, JH Park, Straumal and NK Park; Mater. Lett., 2020, vol.258, article number 126806, pp.1-4)

The development of precipitation-induced medium- and high-entropy alloys (MEAs and HEAs) has been intensively performed recently. This exploration was taken to enhance the mechanical properties of these alloys. The mechanical properties of these systems tended to decrease in several circumstances despite to a remarkable strength-ductility balance. The implementation of precipitation hardening by substitutional element addition, i.e. Al nanoprecipitate, was reported to be effective in improving the mechanical properties of MEA. As for the utilization of interstitial element, it was observed that nitrogen addition led to nitride precipitate formation in HEA. Considering the abundance availability and cost-effectiveness of nitrogen, it is then fascinating to investigate the effect of nitrogen addition toward the microstructure and precipitate formation in MEAs and HEAs. Herein, we investigated the precipitate formation by nitrogen addition in equiatomic CoCrFeMnNi HEA. The equiatomic CoCrFeMnNi was chosen, as aside from being widely studied HEA system, CoCr-FeMnNi can maintain its face-centered cubic (FCC) phase over a wide temperature range. The investigation was also performed to observe the behavior of the formed precipitates in N-CoCrFeMnNi.

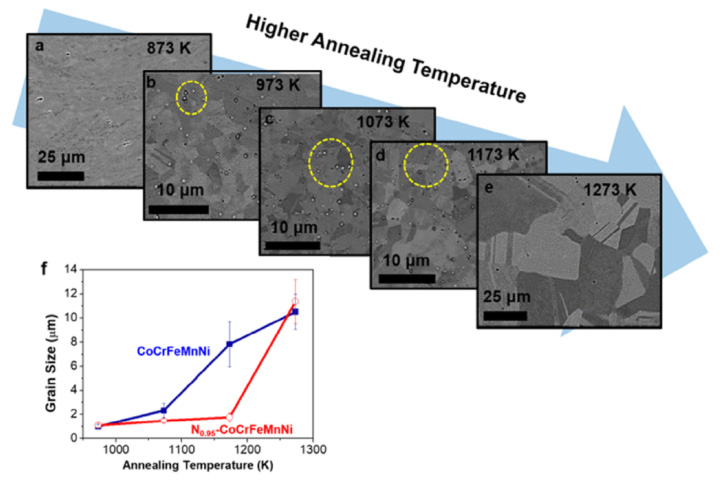

SEM-BSE observation on (a) NC873, (b) NC973, (c) NC1073, (d) NC1173, and (e) NC1273; (f) Grain size comparison between the as-recrystallized N0.95-CoCrFeMnNi and CoCrFeMnNi.

Precipitate behavior in nitrogen-containing CoCrNi medium-entropy alloys

(Jodi, NK Park and JH Park; Mater. Character., 2019, vol.157, article number 109888, pp.1-9)

The development of medium-entropy alloy (MEA) and high-entropy alloy (HEA) systems has been extensively studied in the recent years. The classification between medium-entropy alloy (MEA) and high-entropy alloy (HEA) is based on the mixing entropy (ΔSmix) value. An alloy is categorized as LEA when the ΔSmix is ≤0.69R. Meanwhile, an MEA has a ΔSmix value between 0.69R to 1.61R. Meanwhile, HEA exhibit a ΔSmix value of ≥1.61R. Both of these alloy systems are widely recognized for exhibiting complex chemical compositions and are composed of various elements in equiatomic or near equiatomic ratios between 5 and 35 at.%. Distinctively, this configuration causes a high entropy effect in MEAs and HEAs, thereby leading to the formation of a simple solid solution phase instead of forming intricate intermetallic compounds. The presence of various elements also causes severe lattice distortion effects in MEAs and HEAs, which leads to considerable solid solution strengthening and enhances the mechanical properties in MEA and HEA systems.

In conventional alloys, the addition of nitrogen has been well known to induce the formation of nitride precipitates on microstructures. The formation of nitride precipitate, combined with the solute nitrogen atom in conventional alloys was observed to be able to improve the mechanical properties. The effect of nitrogen addition in MEA and HEA systems, particularly in the MEA system of CoCrNi, toward the formation of nitride precipitate is hence highly interesting to be studied. In this study, we focused on investigating the effect of nitrogen addition toward nitride precipitate formation in the N-CoCrNi system. The behavior of nitride precipitate formation in the microstructure of N-CoCrNi system was also evaluated in this investigation.

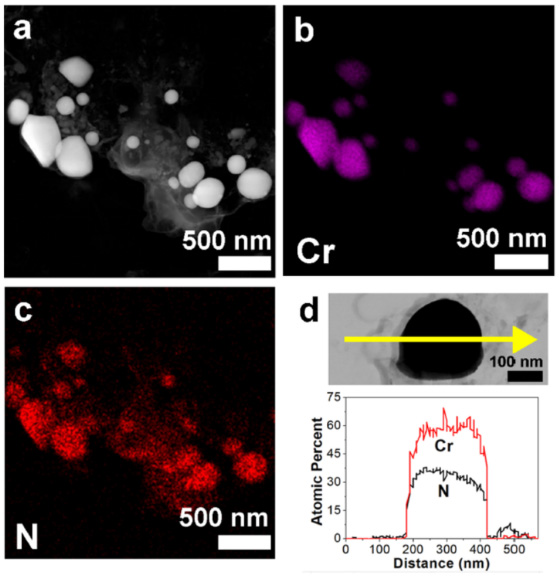

TEM observation on the precipitate of the as-annealed 1273 K N-CoCrNi. (a) Dark-field observation, (b) EDS mapping of Cr, (c) EDS mapping of N, and (d) TEM-EDS line observation.

Characterization of non-metallic inclusions and their influence on the mechanical properties of a FCC single-phase high-entropy alloy

(Choi, Lim, Na, Glatzel and Park; J. Alloys & Compd., 2018, vol.763, pp.546-557)

A high-entropy alloy (HEA) is a new alloy concept, which was first introduced by the research of Yeh et al. and Cantor et al. in 2004. Conventional alloy systems, such as steels and aluminum alloys, are composed of one principal element and contain a small quantity of additional elements in order to enhance the properties of principal element or to gain secondary properties. On the other hand, HEA comprises several principal elements. Despite the preconception that microstructures of these multicomponent systems are complex due to the formation of intermetallic compounds or segregated phases, HEAs usually have a single phase, such as FCC or BCC, or a simple microstructure of two dominant phases. The simple structure of HEA was believed to result from one of the core effects observed in HEA (e.g., the high-entropy effect). In addition, the sluggish diffusion effect due to different sizes of the elements, which distorts the lattice, and limits the formation of new phases by diffusion.

Despite of the importance of understanding the characteristics of NMIs, there are few systematic studies focused on the effects of NMI in HEA. In order to utilize the promising properties of HEA, quantitative characterization of NMI is essential, and further development of methods to reduce NMI particle formation is also highly desired. Therefore, in this study, the content of impurities and the extent of NMI precipitation in the as-cast CoCrFeMnNi HEA were characterized. The impurity contents, such as carbon, sulfur, nitrogen, and oxygen, in the CoCrFeMnNi alloy were measured with combustion analyzers, and the NMIs that result from these impurities were predicted with a thermodynamic computation program, FactSage™7.0. The two-dimensional and three-dimensional morphologies, size distributions, and chemical compositions of the NMIs were investigated by employing scanning electron microscopy combined with energy dispersive spectroscopy (SEM-EDS) measurements. Finally, we evaluated the effect of these inclusions on the tensile properties of the HEA. Those characterizations were also conducted in order to examine the applicability of as-cast HEA as likely as many kinds of Al and Mg alloys in their use of as-cast alloys.

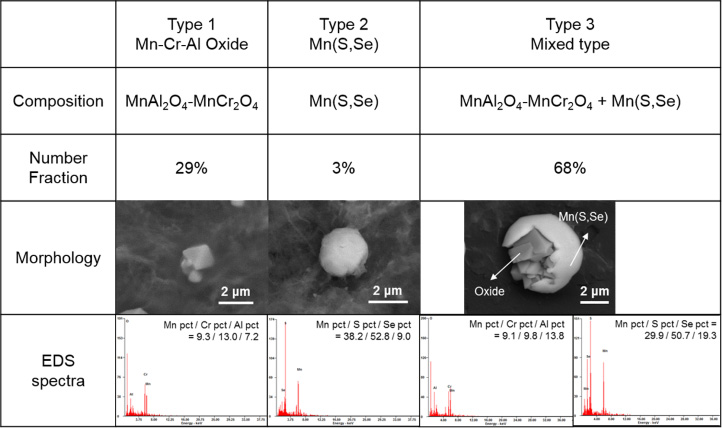

The composition, representative morphology, and the EDS spectra of three types of inclusions.

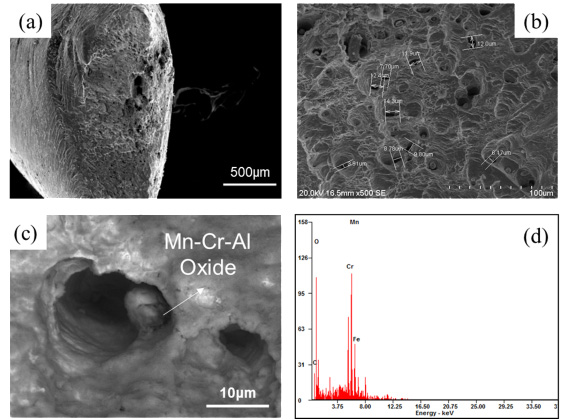

(a) Fractography at a magnification of 35´, (b) 500´ and (c) Mn-Cr-Al oxide particle in dimple on a fracture plane, (d) EDS spectra of the inclusion.

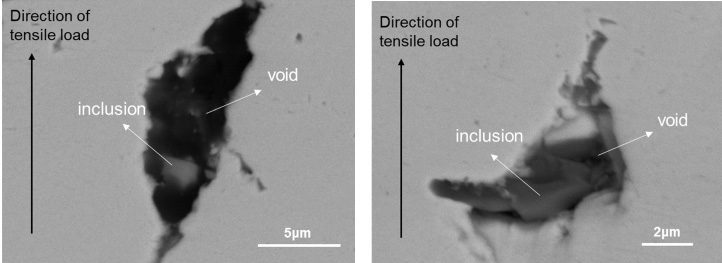

Micro-voids and inclusions in the voids observed from a longitudinal cross section of a fractured specimen.